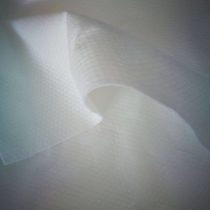

*Spun lace non-woven is made of different raw materials such as adhesive, terylene, bi-component fiber, bamboo fiber and tencel fiber, which can be produced into different products to meet different demands and purposes of the customers.

The process “spun lacing”: High-pressure water flows are shot into the fiber web to make the fibers inter-wined. The originally loose fiber web thus develops a certain strength and a complete structure. Its processes include: measurement and blending of fibers, opening and removing foreign matters, carding with machinery and web forming, fiber mesh wetting, spun lace inter-wining, surface treatment, drying, reeling, test, packaging and warehousing. The spun lacing device uses a fast-flowing high-pressure water flow to shoot into a fiber web so that the fibers are re-structured and inter-wined to a non-woven with a complete structure, a certain strength and other properties. Unlike common needle non-woven fabrics, this kind of water-needle non-woven is the only non-woven to make the final products similar to textile products whether in feel and property.

*Standard

Standard: 25gsm-160gsm, maximum width 3,200mm

Spunlace nonwoven fabric:

--1. Soft and with an excellent drapability;

--2. With a high strength;

--3. Highly absorptive and quick wetting;

--4. Resistant to fluffing;

--5. Washable;

--6. Free of chemical additives;

--7. Appearing similar to textile products.

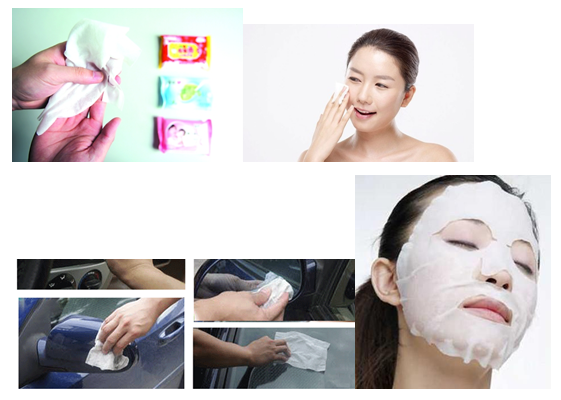

*.Applications

Articles of daily use: wiping cloth, wet tissue, compressed towel, facial mask, baby wiping cloth

Medical treatment and hygiene: medical bed sheet, pillow case, tablecloth

Industrial supplies: wiping cloth, interlining, PVC synthetic leather base cloth

20% Vis 80% Pes Spunlace Nonwoven Fabric Parallel Lapping For Wet Wipes

Anti Bacterial Spunlaced Non Woven Fabric Polyester Material for home textile

Hendar Plain Spunlace Nonwoven Fabric 95% Tencel 5% Bamboo No Skin Irritation

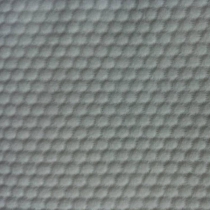

Viscose Polyester Pearl Spunlaced Cloth For Disposable Wipes

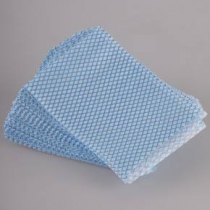

Mesh Spunlace Nonwoven Fabric Eco Friendly Recyclable For Cleaning Rags

Soft Stretch Resistant Non Woven Spunlace Fabric With Customizable Color

Pearl Spunlaced Cloth Soft Hydrophilic Breathable For Towels

Eco Friendly 35gsm Spunlace Nonwoven Fabric Strong Water Absorption Wood Pulp Fabric

Rags / Wipes Spunlace Nonwoven Fabric Component Ratio Customized

Soft Absorbent Pearl Spunlace Non Woven Fabric Recyclable Breathable

Non Woven Spunlaced Mesh Cloth Recyclable Customized Composition

Viscose Polyester Pearl Spunlace Cloth Disposable Wipes Spunlace Nonwoven Fabric

Breathable Spunlace Nonwoven Fabric Custom Pattern For Disposable Wipes

Water Spiny Cloth Spun Lace Non Woven Fabric Dry Towel Wipe Pot For Kitchen

Wood Pulp Compound Spunlace Nonwoven Fabric 10-320cm Customised Width For Glasses Cloth

Wavy Grain Spunlace Nonwoven Fabric Environmentally Friendly For Hand Wipes

Pearl Spunlace Nonwoven Fabric For Disposable Sanitary Eco Friendly

White Plain Spunlace Cloth Spunlace Nonwoven Fabric For Underwear